Safety Alert

The UK’s Health and Safety Executive (HSE) recently alerted industry to a serious technical fault identified with mast climbing work platforms (MCWPs), used widely in construction projects for work on tall buildings.

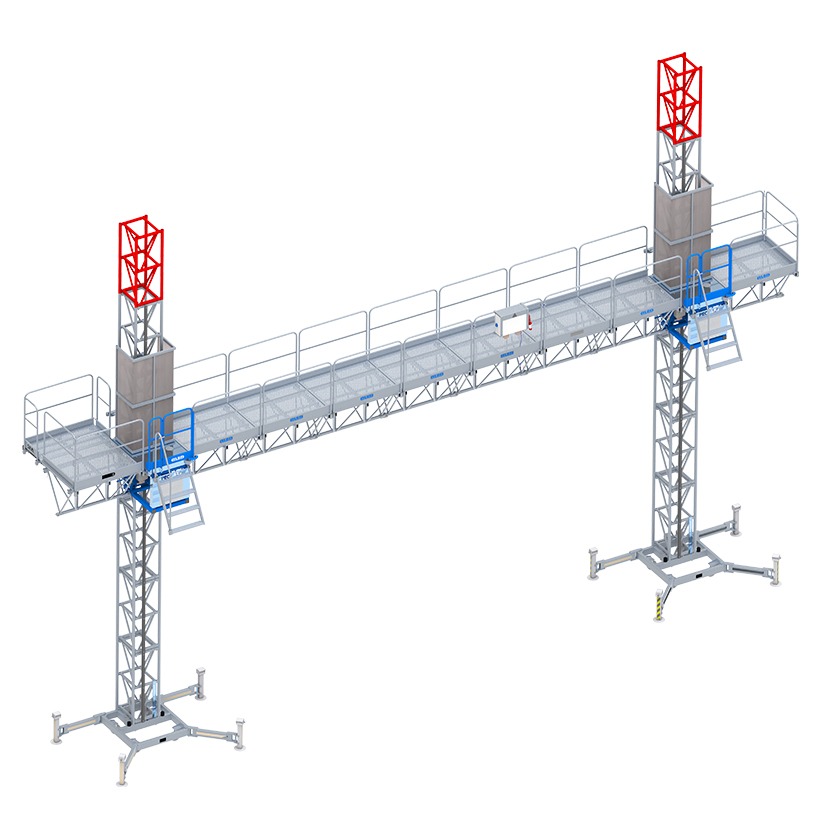

MCWPs comprise of a powered work platform attached to one or more vertical masts, within which mechanical drive units are housed.

The HSE highlighted that MCWPs could fall from height where mechanical faults in drive units go undetected. If not rectified, the fault could cause serious injury, or even death.

The UK’ HSE reported the following: “some MCWPs, which rely on two independent motor drive units per mast as the means to prevent the platform falling with overspeed, are not fitted with suitable and sufficient controls to manage this risk. Failures in drive units can be such that neither the centrifugal brakes (intended to limit the speed of descent) nor the automatic brakes (intended to engage when powered travel is stopped) within the drive units are able to have an effect. Malfunctions in drive units which endangers proper function are foreseeable and unless a means of detection of such malfunctions is provided there is a risk of platforms falling with overspeed.”

Immediate Actions Required

Check that the necessary control measures are in place for all MCWPs in use or in standby. Where the control measures are not in place, the HSE (UK) advises to withdraw the MWP from use until those responsible for supply, installation, use, inspection, servicing, maintenance and for thorough examination ensure the following:

- there is the means to identify a loss of mechanical integrity in each drive unit where this is the system to prevent falling with overspeed

- each individual drive unit is fitted with a mechanical device, eg centrifugal brake, that automatically prevents the work platform descending at excessive speed

- damage to drive units due to platforms being powered onto buffers/base frames is prevented

- platforms and associated equipment are not damaged by physical overloading

- thorough examinations, inspections and tests, and visual and functional checks are appropriately planned and carried out.

Other Actions Advised

The following protective measures are advised by the HSE (UK):

- Detect malfunctions in each drive unit which endanger proper function – where two or more drive units are installed as the system to prevent falling with overspeed, ensure that:

- there is the means to detect malfunctions in each drive unit that could indicate a loss of mechanical integrity which results in a differential in the current demand between each drive unit, exceeding 25% of the full load current

- detection is in accordance with the manufacturer’s instructions, e.g. it initiates a stop command and generates audio-visual alarms

- the means of detection is functionally tested in accordance with the relevant technical standard or the manufacturer’s instructions.

- Prevent falling with overspeed – where two or more drive units are installed, ensure that each individual drive unit is fitted with a mechanical device, e.g. a centrifugal brake, that automatically prevents the work platform exceeding 0.4 m/s descent speed.

- Prevent failure of the automatic brakes –

- Operators are competent and conform to the manufacturer’s instructions for emergency lowering of the platform, e.g. to prevent overheating

- Check brakes for wear and assess them against discard criteria in accordance with manufacturer’s instructions

- Carry out functional checks of the individual automatic brake on each of the paired drive units in accordance with the manufacturer’s instructions.

- Prevent damage to drive units caused by contact with buffers or base frames –

- Ensure limit switches are appropriately positioned such that the lowest level that stopping is initiated by a terminal switch is achieved before contact with the buffers (and before contact with the final limit switch)

- Include functional tests of limit switches in checks and maintenance inspections.

- Prevent damage due to physical overloading –

- Clearly / indelibly affix to the platform the safe working load for platform configuration

- Include functional testing of the overload warning device(s), if fitted, in maintenance inspections.

- Prevent failure due to defects or deterioration being undetected, as part of your risk management and control arrangements –

- Review risk assessments with a focus on periodicity of inspections and thorough examinations and tests, reference to national regulations and the manufacturer’s manual

- Ensure periodic inspections, measurements and checks include those items listed by the manufacturer in their maintenance and service schedule.

Further Guidance

- Health Services Executive (UK). Mast climbing work platforms: Failure to detect mechanical failure in drive units leading to uncontrolled fall of platforms. Available at: https://www.hse.gov.uk/safetybulletins/mast-climbing-work-platforms-mechanical-failure.htm

- IPAF. Guidelines for the Safe Use of Mast Climbing Work Platforms (US Edition 2010). Available at: https://www.ipaf.org/en