What Happened / Impact?

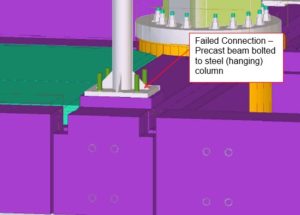

- An incident occurred where a bolted connection securing a precast beam to a structural steel hanger failed.

Refer to Figure 1. - Following examination, it was clear that the retaining bolt support mechanism failed, in a progressive manner over several hours, resulting in the partial collapse of a section of precast.

- Subsequent investigations found that incorrect nut specification had been used to retain the four bolts for this specific connection.

Why it Happened?

- The connection that failed had nuts of an incorrect sizing fitted to the four bolts; the bolt type was M33, whereas the nuts fitted were type M36.

- Two experienced and trained operatives placed the nuts on the bolts and tightened them with spanners. At no stage during the process did the operatives note any concerns in fixing the nuts.

Immediate Learnings / Recommendations

Immediate Learnings:

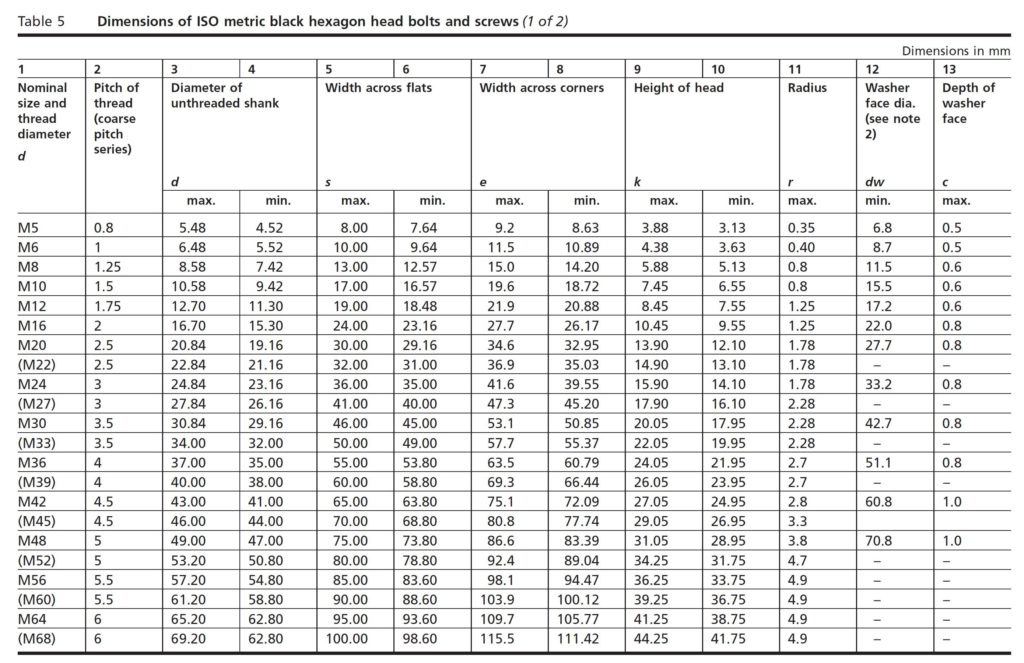

Table 5 from BS 4190:2014 states (at the bottom of the page) that “sizes shown in brackets are non-preferable”. Post incident, the advice offered, to avoid an incorrectly sized nut being placed on a bolt, would be to implement the recommendations of the BS standard and eliminate the use of non-preferred sizes, as displayed in brackets on Table 5 of BS 4190:2014. This would maintain a larger differential in diameters, thus allowing for clearer identification of incompatible nuts and bolts.

Key Recommendations:

- Eliminate non-preferred sizes (as shown in brackets on Table 5 of BS 4190:2014), particularly during the design phase. Refer to Table 1

- It is important to communicate to workers the criticality of selecting nuts and bolts of a correct, compatible size and thread pitch. Closely-sized but incompatible nuts and bolts may be easily threaded and can appear secure until such time as a load is applied, whereupon the risk of failure occurs.

Table 1 – Extract from BS 4190:2014

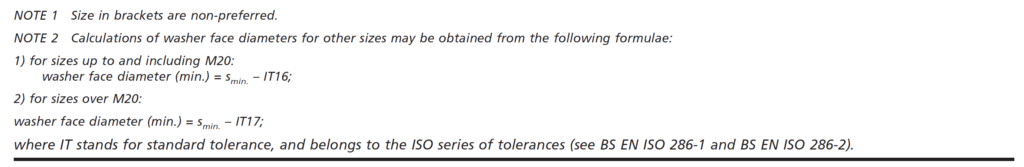

- If no torque value is provided, it should be sought from the respective designer or manufacturer. For many non-preloaded (ordinary bolted) connections, the designer may not be required to provide a torque value. If this is the case, then the torque values in Table 2 should be used to verify that any ordinary bolted connection is correctly tightened.

Table 2 – Extract from Steel Construction Institute – Technical Advisory Note AD 302

- All connections designed to withstands significant loads shall be identified and evaluated in a design risk assessment, with appropriate controls specified.

- This specific incident occurred in a heavy structural connection; however, it could occur in any nut and bolt connection (e.g. threaded bar and uni-strut drops, relief angles, shutter connections, etc). All bolted connections should be reviewed to ensure conformity of nut and bolts and that “non-preferred sizes” as per table 5 of BS 4190:2014 are not selected for use.

- Where applicable, a Vernier Callipers, thread Pitch Gauge and Torque Wrench should be available onsite for site verification of bolt and nut compliance.

Figure 2 – Pitch Gauge

Figure 3 – Digital Vernier Callipers