What Happened / Impact?

An accident that occurred on a construction site involving hydraulic breakers identified some poor working practices that have reportedly become commonplace. Though the injuries suffered were very minor, there was potential for more serious injury or harm.

A review of the activities leading to the accident determined the following:

- The task undertaken was to remove and replace the chisel from a hydraulic breaker.

- The breaker was positioned vertically whilst attached to the excavator, with the chisel being pushed into the ground.

- The fitter then proceeded to remove the securing pins (which hold the chisel in place) by knocking these out with a hammer.

- Whilst doing this, the machine operator who was trying to assist, was observing the operation too closely, resulting in the pin suddenly ejecting from the breaker under considerable force, striking the individual on his head.

Immediate Learnings / Recommendations

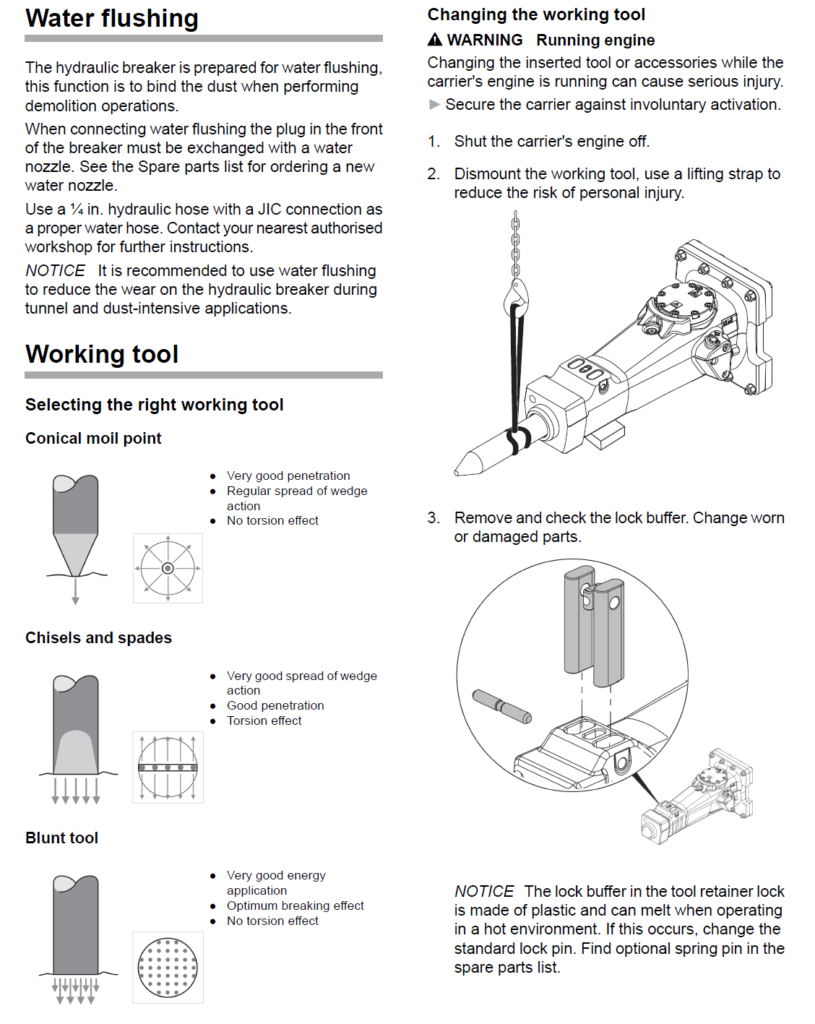

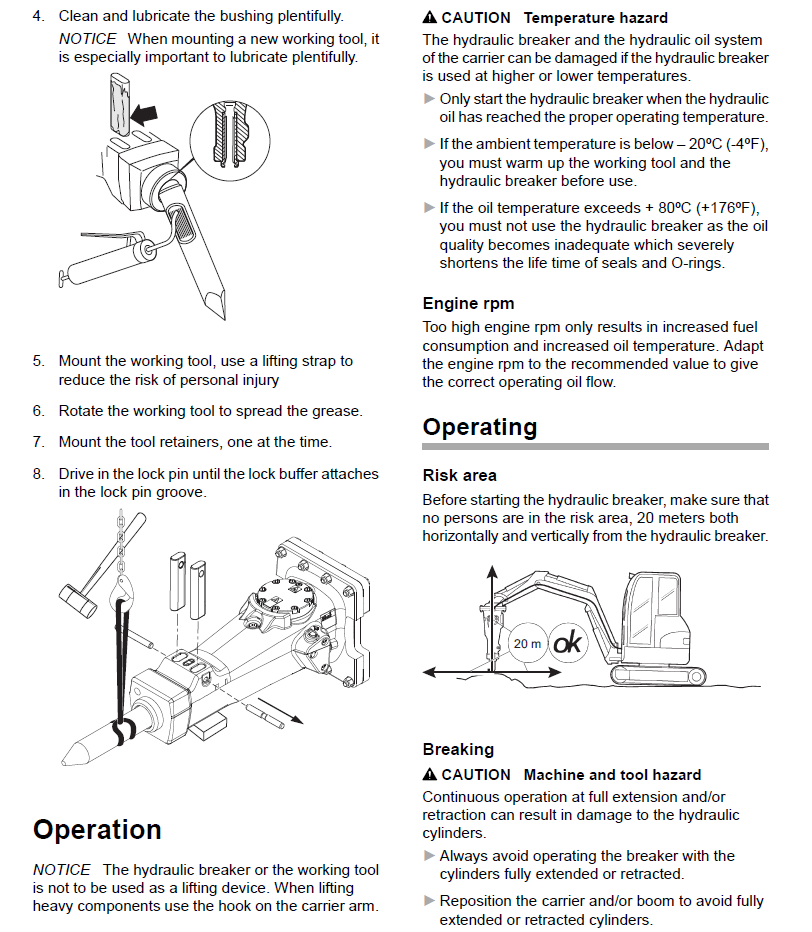

- As illustrated, the manufacturers’ instructions require the breaker to be positioned horizontally on the floor and detached from the excavator. The arm of the excavator, via a suitable sling, is then used to lift and support the weight of the chisel. The securing pins are then removed.

- The excavator lifts and supports the old chisel and is then used to replace the new chisel into the breaker. The securing pins are then inserted safely.

- Several highly skilled fitters were asked: “How do you change a chisel?” They all incorrectly failed to note that the breaker must be positioned horizontally on the ground and disconnected from the dipper arm of the excavator!

- A copy of the manufacturer’s instructions was not available on site or referred to before the task was undertaken. These can be obtained from the manufacturer or in most cases downloaded from the Internet.