What Happened?

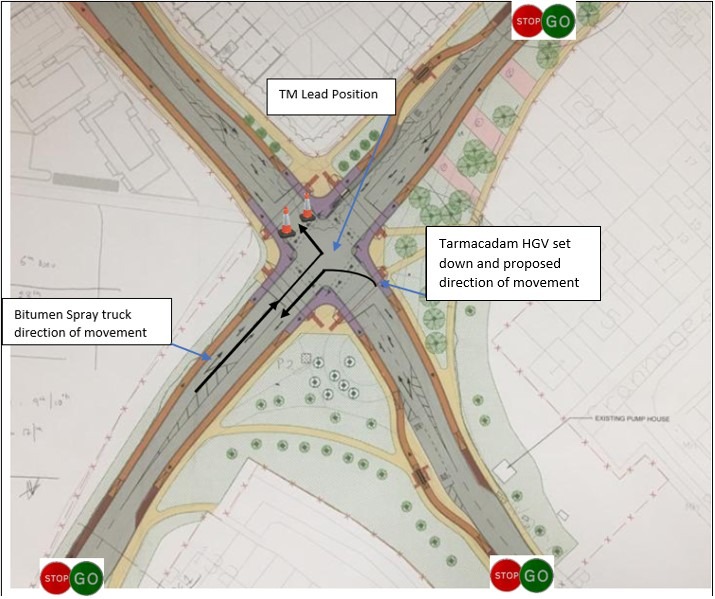

Resurfacing works were being carried at a newly installed crossroad junction. The Team Lead for the Traffic Management (TM) controllers was managing the movement of traffic between the three operating junctions and the movement of construction traffic in the zone.

- A bitumen spray truck requested egress from within the traffic management.

- The TM Lead ordered an all stop for traffic from his 3 fellow crew members directing traffic from the Southern, Eastern and Western approaches to the newly installed Junction.

- The TM lead directed the Bitumen truck to the newly installed road. As the bitumen truck proceeded towards the holding area the TM lead gave directions to a Tarmacadam HGV to begin reversing towards the area where the bitumen spray truck had come from.

- The bitumen spray truck driver overestimated the left-hand turn and was unable to enter via the gates so moved out and pulled forward more to create a greater angle to access the area, the bitumen spray. At this time the TM lead was positioned to the right of the bitumen truck instructing the Tarmacadam HGV to stop reversing as the Bitumen spray truck was still in the way and assumed that the bitumen spay truck was going to continue on straight.

- The TM lead, facing the tarmacadam HGV, stepped back towards the bitumen spray truck on the assumption it was going straight. At the same time the bitumen spray truck driver swung the truck left resulting in the back of the bitumen spray truck swinging out to the right. The protruding back steps on the bitumen spray truck struck the TM lead in the left shoulder knocking him to the ground. The TM lead got back to his feet and stated he was unhurt.

Corrective Actions

- Toolbox talk undertaken on all of the contractor’s sites.

- A full review of site traffic movement carried out on all contractor’s sites examining their current provisions for vehicle movements within their sites, including space provided, banksmen, avoidance of requirements to reverse, number of vehicle movements at any time.

- Review of coordination between subcontractors.

Immediate Learnings / Recommendations

- A risk assessment needs to be carried out on the overhanging sections of trucks when operating in tight spaces and be briefed to those working in the vicinity.

- Spotters to ensure, when spotting more than one vehicle, to only allow movement of one vehicle at a time.

- Drivers to be made aware that no manoeuvring of vehicles to take place if the spotter is not facing them or not in a safe position to spot them.

- Spotter to face moving vehicle until fully stopped.

- Spotter to ensure they locate themselves at safe distance from moving vehicles while being aware of driver’s blind spots.

- Drivers only to move on the direction of the spotter.

- Both drivers and spotters to take a moment to communicate their intentions to eliminate either party presuming what the other is doing.