What Happened?

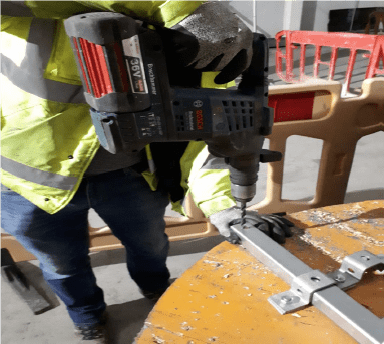

An individual worker was drilling unistrut using a 36-volt battery drill on an upturned cable reel. Top hat unistrut brackets were installed to hold the 1.3m length of unistrut in position while drilling (see figure 1).

The worker was holding the unistrut in place with his left-hand and using the hand-held drill with their right (see figure 2). When drilling the unistrut, the drill slid across the unistrut and met the workers left-hand thumb, piercing the skytec level 5 cut resistant glove and resulting in a serious injury to his thumb.

The injured worker was subsequently brought to hospital for immediate medical attention.

Figure 1: Reconstruction of how the accident occurred

Figure 2: Reconstruction of hand placement, which resulted in injury

Why It Happened?

Immediate Cause:

• The drill slipped and contacted the worker’s thumb.

Underlying Cause:

• Incorrect use of the drill

• Worker used their hand to secure the unistrut.

Root Cause:

• Workstation was not adequate for the task; a pillar drill combined with a workstation would be more appropriate

• The associated Risk Assessment Method Statement (RAMS) and Safe Plan of Action (SPA) did not define the methodology to be used.

Immediate Learnings

1. Dedicated prefabrication areas established on site to include pillar drills

2. RAMS was revised to define the methodology to be used for the task

3. A review of the methodology for similar prefabrication and drilling tasks (e.g. box-trunking) was also undertaken

4. Site stand-down for safety to communicate the lessons learned

5. Targeted training to be conducted to focus on behavioural issues and lessons learned

6. Additional oversight of planned work during peak labour input.