What Happened?

A collaborative review of incidents and near-miss accidents involving Mag Drills (see sample illustration) highlights some lessons learned.

Examples of incidents occurring within the construction sector include:

- Entanglement of high-viz vest with rotating bit, which pulled operative towards drill and jarred individual’s shoulder. A separate event resulted in bruised ribs.

- Mag drill fell from height as not properly secured.

- Thumb injury when drilling uni-strut.

- Finger injury when operator’s finger tangled in swarf (when attempting to clean swarf away from steel).

Why it Happened?

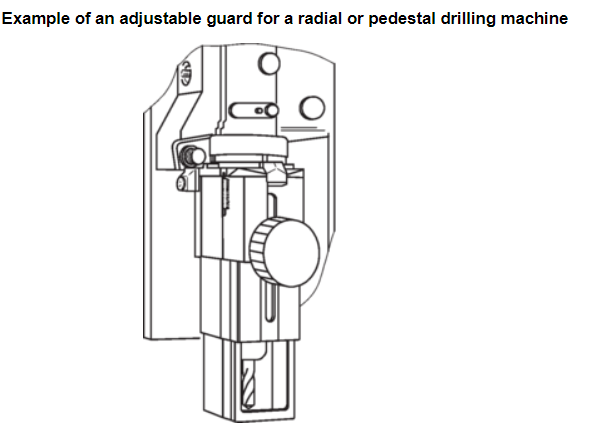

- There is often no guarding, or manually adjustable guards, on the mag drills (as illustrated below). The provision and use of guarding (if used correctly) reduces the risk of injury by protecting against unexpected access, entrapment of loose clothing and the ejection of materials.

- When drilling, the swarf tends to build-up around the drilling bit. Operatives may make the mistake of using their fingers to remove swarf when the bit is in motion; this may result in an injury.

- Mag drills may not be sufficiently secured to prevent unintended movement or falls.

Immediate Learnings / Recommendations

- It is suggested to provide training on the use of Power Tools (e.g. 6-8 mins for each power tool). A template training document is provided here: https://cif.ie/wp-content/uploads/2021/02/SOP_Mag-Drill.docx

- Check if power tools are CE-marked, come with a Declaration of Conformity, and are supplied with user instructions in a language reasonably understood by operator.

- Contact suppliers to determine if guarding is provided and if compliant with EN ISO 14120, ‘Safety of Machinery. Guards. General requirements for the design and construction of fixed and movable guards’.

- NO GUARD = DO NOT USE !

- Promote use of a swarf stick (as illustrated).